The Department of Transportation (DOT) regulates hazardous material (HM) tank training for safety, focusing on interactive valve simulations in tanker simulation units with valves. These advanced units enable trainees to safely practice fluid transfer, emergency response, and routine tasks without real fuel or chemical risks, enhancing DOT compliance and operational skillsets.

In today’s strictly regulated transportation industry, adhering to Department of Transportation (DOT) standards is paramount. This is especially true for training purposes, where DOT compliant training tanks with Betts features offer a cutting-edge solution. The article delves into the intricate world of DOT regulations governing these tanks and highlights the key advantages of Betts simulation units. We explore valved tanker simulation, its benefits, and diverse use cases, providing valuable insights for professionals seeking to enhance safety and efficiency.

- DOT Regulations for Training Tanks

- Key Features of Betts Simulation Units

- Valved Tanker Simulation: Benefits & Use Cases

DOT Regulations for Training Tanks

The Department of Transportation (DOT) sets stringent regulations for training tanks, particularly those used in hazardous material (HM) transportation. These guidelines ensure the safety of both personnel and the environment during the handling and storage of dangerous substances. A DOT compliant training tank with Betts features integrates specialized equipment to mimic real-world conditions, enabling trainees to gain practical experience while adhering to strict protocols.

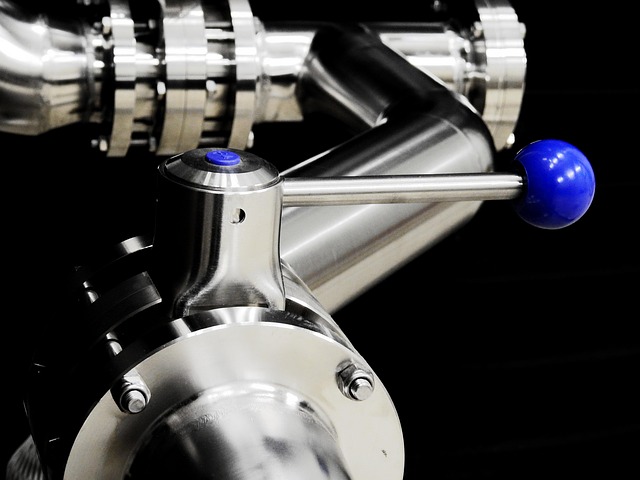

One critical aspect regulated by the DOT is the proper functioning of valves in tanker simulation units. These valves play a vital role in controlling the flow of hazardous materials, and their operation must be thoroughly understood and practiced. With Betts features, training tanks can offer interactive valve simulations, allowing trainees to learn how to safely open, close, and maintain these crucial components, thereby enhancing their overall preparedness for real-world scenarios involving HM transportation.

Key Features of Betts Simulation Units

The DOT compliant training tank with Betts features offers an advanced tanker simulation unit designed for safe and effective driver training. These units come equipped with realistic valve operations, mimicking the controls found in actual tankers. This enables trainees to gain hands-on experience in a controlled environment, enhancing their understanding of critical procedures.

The Betts simulation units are engineered to provide a dynamic learning experience. Their key features include precise valve control, allowing drivers to practice fluid transfer and management scenarios without risks associated with real fuel or chemical handling. This immersive training prepares operators for various situations, ensuring they are equipped to handle emergencies and routine tasks equally well.

Valved Tanker Simulation: Benefits & Use Cases

The valved tanker simulation is a cutting-edge training tool that offers numerous advantages in the realm of DOT compliance and tank operation safety. This innovative technology replicates the intricate mechanics of a real tanker, complete with valves, pressure systems, and fluid flow dynamics. By utilizing this simulated environment, operators can gain hands-on experience without the risks associated with live tank operations.

One of its key benefits is the ability to conduct complex training scenarios, allowing professionals to practice valve manipulation, pressure control, and emergency response protocols in a controlled setting. This is particularly valuable for maintaining DOT regulations, as it enables employees to familiarize themselves with critical procedures, enhancing their overall preparedness. Whether it’s simulating tank loading, unloading, or addressing potential leaks, the valved tanker simulation unit provides a practical solution for honing skills, ensuring efficiency, and reducing errors in real-world tank operations.