Spill response training equipment, including advanced simulators from Betts Parts, is crucial for industrial safety. These tools allow workers to practice various hazardous liquid spill scenarios without exposure to harmful substances, enhancing reaction times and personnel safety in emergencies. By utilizing realistic valve control trainers, organizations can prepare maintenance, operation, and emergency response teams to prevent and manage spills effectively, thereby reducing environmental damage and risks associated with toxic materials.

“In today’s industrial landscape, effective spill response training is paramount for safety and environmental protection. This article explores the critical need for specialized training tools, focusing on valve control simulators equipped with Betts parts. We delve into how these advanced systems, designed for spill response training equipment, offer immersive experiences, enhancing operator proficiency. By understanding the importance of spill response training and leveraging innovative solutions like Betts parts, organizations can ensure better-prepared personnel to handle potential hazards.”

- Understanding Spill Response Training and Its Importance

- Betts Parts: A Comprehensive Solution for Valve Control Simulators

- The Benefits and Features of a Dedicated Spill Response Training Equipment

Understanding Spill Response Training and Its Importance

Spill response training is a critical component of industrial safety, focusing on the rapid and effective containment and cleanup of hazardous liquids. This training equips workers with the knowledge and skills to handle potential spills, minimizing environmental damage and ensuring the safety of personnel. In today’s world, where industrial operations often involve the handling of toxic substances, spill response training equipment plays a vital role in preparing employees for real-world scenarios.

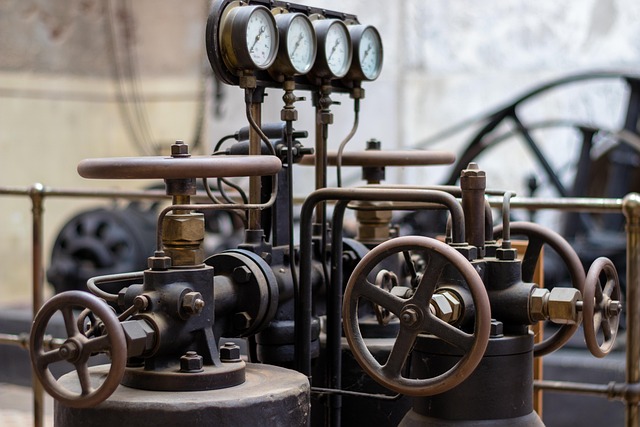

The use of specialized simulators, such as valve control training simulators with Betts parts, allows for realistic practice without risking exposure to harmful materials. These simulators provide a controlled environment where trainees can experience different spill situations, learn appropriate response protocols, and hone their skills in managing valves and containment systems. Effective spill response training not only reduces the risk of accidents but also enables quicker reaction times during emergencies, potentially saving lives and limiting environmental impact.

Betts Parts: A Comprehensive Solution for Valve Control Simulators

Betts Parts offers a comprehensive solution for those seeking advanced valve control training simulators, catering to the specific needs of industries requiring efficient and safe spill response training equipment. Their parts are meticulously designed and engineered to provide a realistic simulation environment, allowing trainees to gain practical skills in managing critical situations involving hazardous materials.

The company’s expertise lies in creating high-fidelity simulation systems that replicate real-world scenarios, ensuring individuals involved in maintenance, operation, or emergency response are adequately prepared. By utilizing Betts Parts, organizations can enhance their ability to prevent and manage spills, thereby reducing environmental impact and potential risks associated with hazardous substances.

The Benefits and Features of a Dedicated Spill Response Training Equipment

A dedicated spill response training simulator, such as those utilizing Betts parts, offers numerous advantages for organizations dealing with hazardous materials. This specialized equipment enables employees to practice and refine their skills in a controlled environment, minimizing risks associated with live demonstrations. It facilitates hands-on learning, ensuring that personnel are well-prepared to handle real-world spill incidents effectively and safely.

The features of such training equipment include customizable scenarios, allowing for a wide range of emergency situations to be simulated. This adaptability is crucial for industries facing diverse challenges, from chemical leaks to oil spills. Additionally, these simulators often incorporate advanced technologies like realistic visual feedback and tactile responses, enhancing the realism and educational value of the training experience. Such immersive training equips workers with the knowledge and confidence needed to respond swiftly and accurately during actual spill events, contributing to improved safety outcomes and operational efficiency.