Tanker simulation units with valves are advanced tools that replicate real-world tanker operations, offering a safe environment for testing and optimizing liquid handling processes before live implementation. In maritime and industrial settings, these units enhance efficiency, reduce costs, and improve safety by allowing engineers to validate control strategies, assess system performance, and train personnel without risks associated with live tank operations. Realistic tank props integrated with valve systems are used in training contexts and for creating dynamic scenes in movies and games, prioritizing safety and realism. Adoption of these technologies has led to improved operational efficiency, reduced downtime, and better resource management across various industries, as highlighted by successful case studies.

In today’s maritime industry, efficient and safe tanker operations are paramount. Realistic tank prop simulations, featuring innovative betts offloading systems, offer a game-changing solution. This article delves into the world of tanker simulation units (TSUs), exploring their role in enhancing efficiency and safety. We’ll dissect the concept of betts offloading, detail key components for comprehensive guidance, and highlight the importance of valve systems in TSUs through compelling case studies. Discover how this technology revolutionizes tanker management with advanced simulation capabilities and precise control.

- Understanding Tanker Simulation Units: Their Role and Benefits

- The Concept of Betts Offloading: Enhancing Efficiency in Tanker Operations

- Key Components of a Realistic Tank Prop: A Comprehensive Guide

- Designing for Safety: Incorporating Valve Systems in Tanker Simulations

- Case Studies: Successful Implementations of Tanker Simulation Units with Valve Technology

Understanding Tanker Simulation Units: Their Role and Benefits

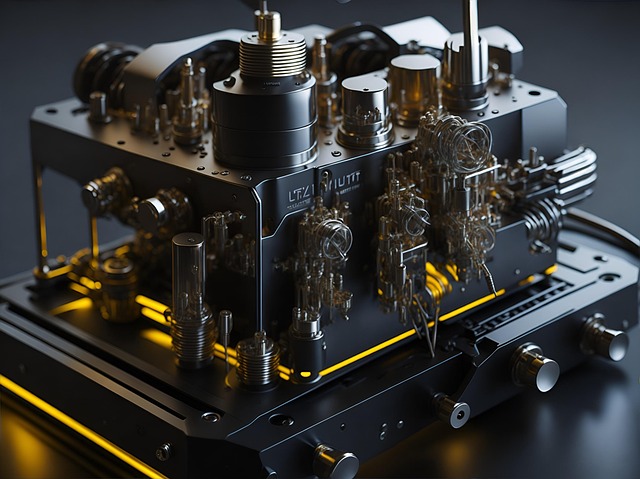

Tanker simulation units, equipped with valves, are essential components in the field of industrial process control and tank management. These sophisticated devices mimic real-world tanker operations, allowing for precise simulations in various settings. By replicating the behavior of liquid flow, pressure changes, and valve interactions, they provide a controlled environment for testing and optimizing processes before implementation in live tank systems.

The role of these simulation units is multifaceted. They enable engineers and technicians to validate control strategies, assess system performance, and identify potential issues without the risks associated with physical testing. This not only saves time and resources but also enhances safety by allowing for detailed analysis and adjustments before operational deployment. With their ability to simulate complex tanker operations, these units serve as valuable tools in ensuring efficient, secure, and effective liquid handling processes.

The Concept of Betts Offloading: Enhancing Efficiency in Tanker Operations

In the realm of maritime operations, optimizing efficiency is paramount for minimizing costs and maximizing productivity. Betts offloading, a revolutionary concept in tanker simulation, plays a pivotal role in achieving this goal. By mimicking the intricate valve controls and fluid dynamics of real-world tankers, a tanker simulation unit with integrated valves allows operators to practice and refine their skills without the risks associated with live tank operations.

This innovative approach streamlines the process by enabling precise control over offloading scenarios, such as managing flow rates, monitoring pressure, and simulating various tank conditions. The simulator’s capabilities extend beyond mere replication; it enhances decision-making skills by providing real-time data and feedback, effectively preparing personnel for unexpected challenges in open-water settings.

Key Components of a Realistic Tank Prop: A Comprehensive Guide

A realistic tank prop, designed for tanker simulation, is a complex construct that combines several key components to create an authentic and functional model. At its core, this prop features a primary storage container, typically crafted from robust materials like steel or high-density plastics, capable of holding various liquids or substances as per the simulation’s requirements.

The tank’s operational heart lies in its valve system, which enables precise control over fluid flow. This includes an array of valves, such as inlet and outlet valves, pressure relief mechanisms, and shut-off valves, all strategically positioned for easy manipulation during simulations. Additionally, advanced props may incorporate sensors and monitoring systems to track parameters like temperature, pressure, and volume, providing invaluable data for realistic training scenarios. These components collectively ensure the tank prop’s versatility and realism in various industrial and emergency response training contexts, mimicking the behavior of real-world tankers while offering a controlled environment for skill development.

Designing for Safety: Incorporating Valve Systems in Tanker Simulations

When designing realistic tank props for movies, games, or simulations, safety is paramount. Incorporating a tanker simulation unit with valve systems brings an element of authenticity and enhances overall realism. These valves play a crucial role in controlling fluid flow, mirroring real-world industrial processes. By integrating precise valve controls, the tank prop can accurately portray various scenarios, from filling and offloading operations to emergency shutdowns, ensuring both visual accuracy and narrative flexibility.

The use of a tanker simulation unit with valve systems allows for intricate storytelling. Designers can create dynamic scenes where characters interact with the tank, whether it’s monitoring fluid levels, adjusting valve positions, or responding to unexpected events. This attention to detail not only makes the prop more compelling but also adds depth to the narrative, engaging audiences in a more immersive experience.

Case Studies: Successful Implementations of Tanker Simulation Units with Valve Technology

In recent years, the adoption of tanker simulation units equipped with valve technology has significantly enhanced operational efficiency in various industries. These innovative systems mimic real-world tank operations, allowing for precise control and monitoring of fluid transfer processes. Case studies across different sectors demonstrate the successful implementation of these simulations, leading to improved safety, reduced downtime, and optimized resource management.

For instance, refineries and chemical plants have leveraged tanker simulation units with valve technology to streamline their complex logistics. By simulating tank offloading operations, companies can identify potential issues before they occur, ensuring safer and more efficient material handling. Similarly, in the maritime industry, these simulations play a pivotal role in training personnel for various scenarios, from emergency response to routine loading and unloading procedures.